The oceans, once considered the final resting place for plastic waste, may hold an unexpected key to solving humanity's mounting pollution crisis. Recent discoveries of marine microorganisms capable of breaking down polyethylene terephthalate (PET) have sparked a revolution in industrial biotechnology. These microscopic "enzyme warriors" are now at the forefront of developing scalable solutions for plastic degradation.

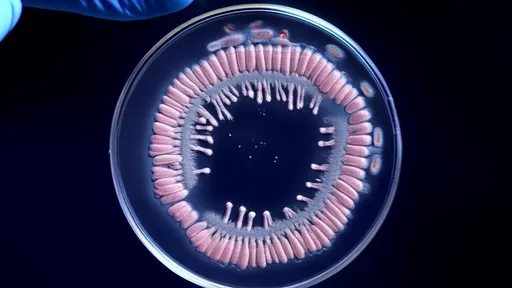

Scientists first stumbled upon this remarkable capability in 2016 when Japanese researchers identified Ideonella sakaiensis, a bacterium that had evolved to consume PET as its primary food source. This discovery sent shockwaves through the scientific community, revealing that nature had already begun adapting to human-made pollutants. Subsequent investigations of marine microbial communities uncovered dozens of additional species with similar plastic-degrading abilities, each employing slightly different enzymatic approaches to dismantle polymer chains.

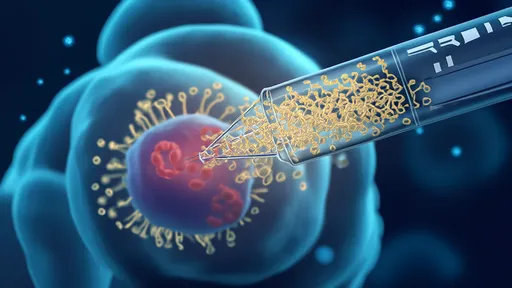

The industrial potential of these biological systems became immediately apparent. Traditional mechanical recycling methods for PET suffer from significant limitations - each recycling cycle degrades material quality, and contamination often renders collected plastic unrecyclable. Enzymatic depolymerization offers a fundamentally different approach, breaking plastics down to their molecular building blocks for true circular reprocessing.

From laboratory curiosity to industrial reality, the path has required overcoming substantial technical hurdles. Early versions of PET-degrading enzymes worked too slowly and at temperatures far below those needed for industrial processing. Through advanced protein engineering techniques including directed evolution and rational design, researchers have boosted enzyme efficiency by over 100-fold since initial discovery. The current generation of engineered enzymes can operate at temperatures above 70°C, close to PET's glass transition temperature where the plastic becomes more accessible to biological breakdown.

Several biotechnology startups have emerged to commercialize these discoveries. Companies like Carbios in France and Protein Evolution in the United States are building demonstration-scale facilities that combine enzymatic treatment with conventional recycling infrastructure. Their hybrid approach uses enzymes for selective depolymerization followed by traditional purification and repolymerization processes. This biological-chemical combination achieves what neither method could accomplish alone - high-quality recycled PET suitable for food-grade applications.

The marine origin of these plastic-eating enzymes presents both opportunities and challenges for industrial scaling. Salt-tolerant enzymes derived from ocean microbes show particular promise for processing plastic waste collected from marine environments, which typically contains high salt concentrations that would inhibit most industrial enzymes. However, maintaining consistent enzyme performance across varying waste streams requires sophisticated feedstock preparation systems to remove contaminants and standardize input materials.

Economic considerations will ultimately determine how quickly enzymatic recycling displaces conventional methods. Current projections suggest that at commercial scale, biologically recycled PET could achieve price parity with virgin plastic within the next 3-5 years, especially as carbon pricing mechanisms make fossil-derived plastics more expensive. The environmental benefits are already clear - life cycle analyses show enzymatic recycling reduces energy consumption by 30-50% compared to producing new PET from petroleum.

Perhaps most exciting is the emerging evidence that marine microbes continue to evolve new plastic-degrading capabilities. Recent studies have identified enzymes capable of breaking down polyethylene and polypropylene, plastics previously considered non-biodegradable. This suggests we may be witnessing the early stages of a natural evolutionary response to plastic pollution, with microorganisms developing biochemical solutions to what humans created through chemical engineering.

As industrial applications progress, researchers caution that biological recycling shouldn't be seen as a license to continue unchecked plastic production. Even optimized enzymatic processes have limits, and preventing plastic waste should remain the priority. However, for the millions of tons of plastic already in our environment and waste streams, these marine-derived enzyme systems offer something rare in the environmental technology field - a solution that works with nature rather than against it.

The coming decade will likely see enzymatic recycling grow from laboratory demonstrations to standard industrial practice. Major consumer brands have already begun incorporating biologically recycled PET into their packaging, with several multinational companies making commitments to scale up usage as capacity becomes available. What began as a curious observation about ocean microbes may well transform into one of the most significant environmental technologies of the 21st century.

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025