In the heart of urban apartments and suburban homes, an unlikely solution to the global food waste crisis is quietly thriving. Black soldier fly larvae, often dismissed as mere pests, are being harnessed as nature's most efficient protein factories on balconies and small-scale farms worldwide. These unassuming insects possess an extraordinary ability to devour kitchen scraps at astonishing rates while converting them into nutrient-rich animal feed.

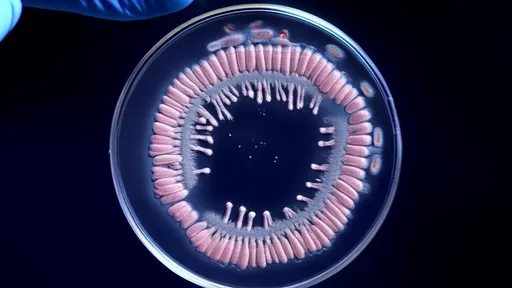

The black soldier fly (Hermetia illucens) has emerged as a champion of circular food systems. Unlike traditional composting methods that simply break down organic matter, these remarkable insects actively transform food waste into valuable biomass. Their larvae can consume twice their body weight daily, processing everything from vegetable peels to spoiled grains with equal enthusiasm. What makes this process truly revolutionary is the output - high-protein larvae that can replace fishmeal in aquaculture or serve as poultry feed, closing the nutrient loop in our food chain.

Urban farmers and sustainability enthusiasts are building miniature bioreactors on their balconies, using stackable containers that allow the flies to complete their life cycle while processing household food waste. The system requires minimal space and maintenance - adult flies don't bite or spread disease, and their self-harvesting behavior means mature larvae crawl out of the compost when ready for collection. This makes black soldier fly cultivation particularly suitable for dense urban environments where traditional composting might be impractical.

The nutritional profile of black soldier fly larvae rivals conventional protein sources. Analysis shows the dried larvae contain 42-45% protein, 35% fat, and essential amino acids comparable to fishmeal. Perhaps more importantly, they can be raised on food waste that would otherwise emit methane in landfills. Research indicates that converting just one ton of food waste through black soldier flies can prevent approximately two tons of CO2 equivalent emissions while producing 100-150 kg of high-quality protein.

Commercial operations are scaling this concept globally, but the true democratization of this technology happens at household levels. Innovative startups now offer complete balcony-sized kits with everything needed to start a personal protein factory: fly colonies, rearing containers, and detailed instructions. These systems typically process 2-5 kg of kitchen waste weekly while producing enough larvae to supplement feed for backyard chickens or aquaponic fish.

Beyond waste reduction, black soldier flies offer food security benefits. The larvae can be dried and stored for extended periods without refrigeration, creating a resilient protein reserve. In developing regions, small-scale fly farming provides affordable feed alternatives that reduce dependence on imported soy or fishmeal. Even the residual compost (frass) serves as a potent organic fertilizer, completing the zero-waste cycle.

Regulatory frameworks are gradually adapting to this emerging industry. The European Union approved processed animal proteins from insects for aquaculture feed in 2017, with poultry and pig feed approvals following. Similar regulatory progress is occurring in North America and Asia, though home production for personal use typically falls outside strict regulations. Scientists continue to refine optimal rearing conditions, with recent breakthroughs in automating temperature and humidity control for balcony-scale operations.

The psychological barrier remains the greatest challenge to widespread adoption. Many potential users initially recoil at the idea of intentionally breeding flies, despite their clean nature compared to houseflies. Early adopters emphasize the satisfaction of watching food scraps transform into valuable resources before their eyes. Cooking demonstrations using oil made from black soldier fly larvae help normalize the concept, though most home production focuses on animal feed rather than direct human consumption.

As climate change accelerates and global protein demand grows, decentralized solutions like balcony bioreactors gain importance. Black soldier flies don't require arable land, pesticides, or freshwater beyond what's already in food waste. Their rapid lifecycle (about 45 days from egg to harvest) allows for continuous production. Perhaps most remarkably, these systems turn the linear "produce-consume-dispose" model into a circular economy at the most local level possible - the individual household.

The movement represents more than waste reduction; it's a fundamental reimagining of our relationship with organic matter. Where society sees garbage, black soldier flies see potential. As more people embrace these tiny protein factories, they're not just managing waste - they're participating in a quiet revolution that could reshape how cities handle organic matter in the coming decades.

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025

By /Jul 22, 2025